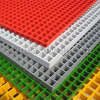

Product Introduction

FRP grating fire resistance mainly relies on glass fiber roving as a production raw material. As one of the main raw materials in the production of FRP grating, glass fiber roving can improve the strength and elasticity of grille, reduce shrinkage and deformation, improve the high temperature resistance and flame retardant performance of the grating, and is the main bearing part of grating. In order to enhance the fire resistance performance of the grating, we can also mix resin materials when adding flame retardant agent, so as to improve the flame retardant effect of the FRP grating.

Our product passes a whole series of well known third party tests with the fire and mechanical properties, and the product sells well all over the world and has a good reputation.

FRP Grating Characteristics

(1) Light weight: standard 25mm high FRP grating board, only 12.5KG per square, which is 1/3 of the weight of traditional steel grid.

(2) Antimagnetic and insulation: In Japan, almost all of the surrounding walkways of power plants, substations and transmission facilities use FRP grating plates;

(3) Chemical corrosion resistance: polyester resin layer makes FRP grating plate resistant to various acid and alkali chemical media.

(4) Anti-skid and anti-aging: FRP grating plate is an inert material, which will not reduce the service life due to harsh environment. It is maintenance-free and replaceable.

(5) Flame retardant: FRP grating plate is not brittle and not hot, and the long-term use environment can be -40 ° C to 90 ° C.

(6) Easy to cut: whole plate grille, portable circular saw can be used on site.

Application Fields

◆ Granary Slope Walkway

◆ Tank Top

◆ Power Plant Water Treatment Workshop

◆ Drain Cover

◆ Sewage Treatment Plant

◆ Car Wash Drainage Board

◆ Ski Resort Glass Reinforced Plastic Stand

◆ FRP Sidewalk

◆ Guardrail

◆ FRP Along the Subway Overhaul Plank Roads

◆ Landscape Decks

◆ FRP Cable Supports

◆ Tree-protected FRP Gratings

◆ Municipal Greening Street Grilles

◆ Factory Operating Platforms

◆ Lawn Barriers

◆ Boat Decks

Conversion Advantages Of FRP Structure Applications

1. Increase load capacity without adding a lot of weight or memory footprint;

2. Improve the seismic capacity of reinforced concrete and masonry structures in earthquake-prone areas;

3. Improve structural integrity;

4. Enhance better load distribution with other structural components;

5. Prevent a gradual decline in structural life;

6. Reduce maintenance costs;

7. Significant changes to the existing weight and dimensions of other structural members are not required for installation.

Reviews

There are no reviews yet.