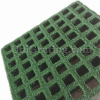

Molded plastic grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thurougly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel.

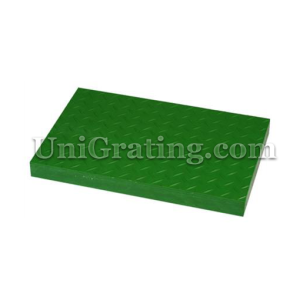

After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface, then can be grinder into smooth top surface, apply grit to make as gritted surface, or add frp flat panel to make as solid top surface.

This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

The Advantages Of Molded Plastic Grating

◆ Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

◆ Fire Resistance

Our special formula provide grating with excellent fire resistant performance. Our FRP gratings pass ASTM E-84 Class 1.

◆ Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Different thickness and mesh size bring the client more choice.

◆ Safety & Anti-slip

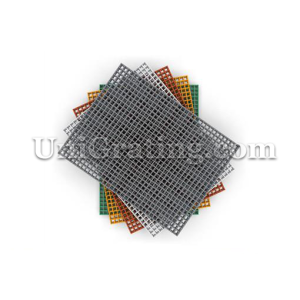

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

|  |  |

Application-Molded Plastic Grating

Molded Plastic Grating can be used in the fields of:

◆ Industry: petrochemical industry;textile printing and dyeing;electronics industry etc.

◆ Food processing;

◆ Sewage treatment

◆ Marine & Ship Building

◆ Civil Architecture

Size Of Molded Plastic Grating

| Mesh Size (mm) | Thickness (mm) | Bar Thickness (mm) | Standard Panel Size(mm) |

| 38×38 | 13 | 6.0/5.0 | 1220×3660,1220×4000,1220×2440,921×3055 1524×4000

|

| 15 | 6.0/5.0 | ||

| 20 | 6.0/5.0 | ||

| 25 | 6.5/5.0 | ||

| 30 | 6.5/5.0 | ||

| 38 | 7.0/5.0 | ||

| 50 | 9.5/7.5 | ||

| 60 heavy duty | 10.5/8.5 | ||

| 70 heavy duty | 11.0/9.0 | ||

| 40×40 | 25 | 7.0/5.0 | 1007×3007,1007×4007,1247×4047,1527×4047 1527×4047 |

| 30 | 7.0/5.0 | ||

| 38 | 7.0/5.0 | ||

| 40 | 7.0/5.0 | ||

| 50×50 | 15 | 6.0/5.0 | 1220×3660,1220×2440,1220×4000 |

| 40 | 6.8/5.0 | ||

| 25 | 7.0/6.0 | ||

| 50 | 8.0/6.0 | ||

| 83×83 | 38 | 7.0/5.0 | 1007×4007,1007×3007,1007×4255 |

| 40 | 7.0/5.0 | ||

| 13×13/40×40 micro mesh | 25 | 6.5/4.5/5.0 | 1247×4047,1007×3007,1007×4047 1527×4047 |

| 30 | 6.5/4.5/5.0 | ||

| 38 | 6.5/4.5/5.0 | ||

| 19×19/38×38 mini mesh | 25 | 6.5/5.0 | 1220×3660,1220×2440,921×3055,1226×4007 |

| 30 | 6.5/5.0 | ||

| 38 | 6.5/5.0 | ||

| 20×20/40×40 mini mesh | 14 | 6.5/5.0 | 1007×3007,1247×4047,1527×4047 |

| 22 | 6.5/5.0 | ||

| 25 | 6.5/5.0 | ||

| 30 | 7.0/5.0 | ||

| 38 | 7.0/5.0 | ||

| 40 | 7.0/5.0 | ||

| 25×25/50×50 mini mesh | 50 | 8.0/6.0 | 1532×4020 |

| 26×26/52×52 mini mesh | 30 | 7.0/6.0 | 1530×4000,1532×4050 1517×4015 |

| 38 | 6.0/5.0 | ||

| 25×50 | 38 | 11.0/9.0 | 1220×1835 |

| 50 | 12.0/9.0 | 1220×1835 | |

| 25×100 | 25 | 7.0/5.0 | 1220×3660,915×3050 |

| 38×100 | 38 | 8.0/6.0 | 1226×3665,921×3050 |

| 25×152 | 38 | 8.0/6.5 | 1220×3660,1220×2440 |

| 38×152 | 38 | 8.0/6.0 | 1220×3660,1220×2440,915×3050 |

Storage, Transportation And Maintenance Of Grating

1. If you need the grating as longtime stock, please ensure all the surface, edges, and corners are protected well be cardboard, foam or something effective packing affairs.

2. It’s the same requirements while transportation.

3. There are no special maintenance for frp grating, easy clean and maintenance free is an advantage of frp grating.

4. The indirect contact of too low(high) temperature and open fire should be prevented.

5. In the process of application, the hard damage caused by the moving, grinding and impact of the steel tool, tool and so on should be prevented.

6. In the practical application, the service life of FRP is shorter in the harsh natural environment, such as high temperature, humidity, and seashore.

Reviews

There are no reviews yet.