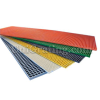

FRP micro mesh grating is the right choice when there is a rolling cart or wheelchair traffic causing large vibrations on the panel. It is specially designed according to the requirements of the ADA. Unlike FRP mini mesh grating, its mesh size is small enough that only one-ninth of the opening of the standard 38mm square mesh grating, which prevents objects as small as 8mm from falling in.

Size-FRP Micro Mesh Grating

Mach’s FRP micro mesh grating refers to the top layer of the grating is a small grid of generally 12.7×12.7, and the bottom layer is a large grid of 30×30.

Specifications in Metric Units

| Thickness (mm) | Mesh Size (mm) Top/Bottom | Bar Thickness(mm) Top/Bottpm | Panel Size (mm) | Open Area | Weight (kg/m2) |

| 30 | 12.7×12.7/38×38 | 7.5&4.5/6.0 | 1220×3660 | 30% | 22.0 |

Specifications in Imperial Units

| Thickness | Mesh Size Top/Bottom | Bar Thickness Top/Bottpm | Panel Size | Open Area | Weight(lbs/sf) |

| 1.2” | 1/2”x1/2”/1.5”×1.5” | 0.30”&0.18”/0.24” | 4’×12′ | 30% | 4.50 |

Mach’s is also available in Mini Mesh Grating, the top layer of the grating is a small grid of generally 19×19, 20×20, 25×25, or 26×26, and the bottom layer is a large grid of 38×38, 40×40, 50×50, or 52×52.

The diffrernce between FRP micro mesh grating and FRP mini mesh grating is that the opening of the Mini mesh is one quarter of the standard 38mm square mesh, which prevents objects as small as 13mm from falling in.

Specifications in Metric Units

| Thickness (mm) | Mesh Size (mm) Top/Bottom | Bar Thickness (mm) Top/Bottpm | Panel Size (mm) | Open Area (mm) | Weight (kg/m2) |

| 25 | 19×19/38×38 | 6.5/5.0 | 1220×4000 | 40% | 16.80 |

| 38 | 19×19/38×38 | 7.0/5.0 | 1524×4000 | 40% | 23.50 |

| 14 | 20×20/40×40 | 7.0/5.0 | 1247×4047 | 42% | 10.50 |

| 30 | 20×20/40×40 | 7.0/5.0 | 1007×4047 | 42% | 18.00 |

| 40 | 20×20/40×40 | 7.0/5.0 | 1007×4047 | 42% | 23.70 |

| 50 | 25×25/50×50 | 8.0/6.0 | 1524×4000 | 55% | 28.50 |

| 38 | 26×26/52×52 | 6.0/5.0 | 1150×4011 | 60% | 19.50 |

Specifications in Imperial Units

| Thickness | Mesh Size Top/Bottom | Bar Thickness Top/Bottpm | Panel Size | Open Area | Weight(lbs/sf) |

| 1” | 3/4”×3/4”/1.5”×1.5” | 0.26”/0.20” | 4’×13′ | 40% | 3.40 |

| 1.5” | 3/4”×3/4”/1.5”×1.5” | 0.28”/0.20” | 5’×13′ | 40% | 4.80 |

| 2” | 1”×1”/2”×2” | 0.31”/0.24” | 5’×13′ | 55% | 5.70 |

Mach’s FRP Molded Grating Raw Material System

| Resin selected type | ||||

| Code | Resin type | Flame retardant performance | Standard color | Recommended use |

| V-CF | Vinyl resign | Oxygen index ≥28 | Grass green, yellow, gray, orange | Acid, alkali solvent and other corrosive environment |

| V-CR | Vinyl resign | Oxygen index ≥35 | Dark gray, black | High flame retardant requirements and high corrosion resistance |

| I-IF | Isophthalic resign | Oxygen index ≥28 | Grass green, yellow, gray | More economical than the above two, and excellent acid resistance, moderate alkali resistance and solvent |

| I-FF | Isophthalic resign food grade | Oxygen index =26 | Yellow, light grey | Mainly used in meat and food processing plants, waterworks |

| O-AF | O-benzene resign | Oxygen index ≥28 | green, grey, yellow | General acid and alkali resistant environment |

| O-AN | O-benzene resign | Oxygen index <28 | Grass green, yellow, gray | Compared with o-af, it is more economical, no flame retardant requirements |

| MP-5 | Phenolic resign | Oxygen index <80 | Brown | High fire provention requirements, low smoke environment |

| Glass fiber roving selected type | ||

| Code | Glass fiber roving type | Recommended use |

| E | Alkali-free roving | Used in applications with high strength requirements and high corrosion resistance |

| C | Medium alkali roving | More economical than E, but lower in strength and better acid resistance |

| Filler selected type | ||

| Code | Filler type | Recommended use |

| ATH | Aluminum hydroxide | Flame retardant, smoke suppression and corrosion resistance |

| CAO | Calcium carbonate | More economical than ATH, no flame retardant requirements |

| PR | No filler, pure resin | Used for high corrosion resistance |

Reviews

There are no reviews yet.