FRP grating cover is on the basis grating plate plus a layer of fiberglass cover. The main difference between it and general FRP grating is reflected in the appearance. The FRP grating is mesh-shaped hollow, while the FRP grating cover is a cover plate added on the basis of the FRP grating.

It has the characteristics of high strength, good performance, energy saving compared with metal materials and non-metal materials. It can be used as structural material for floors, trench covers, platforms, ship decks, stairs, plank roads and other corrosive environments.

Mach’s FRP grating cover has four different surfaces, respectively Smooth Surface, Flat Surface, Gritted Surface and Tread Plate.

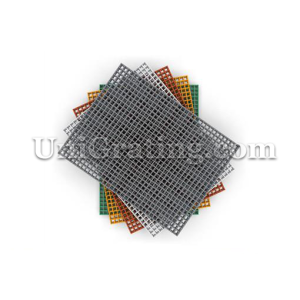

FRP grating cover has flexible design performance. The color of the product can be customized according to the customer’s requirements. The external dimensions can also be cut and spliced into the size required by the customer.

We can also grit on the basis of tread plate to make the cover more slip resistant.

Mach’s FRP grating covers are generally yellow, green and grey. The color made from polyester compatible polyester paste and polyester, so the color is not superficial, so that it keeps the color lasting.

Product Performance

With the addition of the FRP cover, the performance has been improved.

1. The strength and carrying capacity are superior, and one level is upgraded on the previous basis.

2. Wear resistance and corrosion resistance have also improved, the service life is longer than the average grid plate.

3. The anti-slip performance is superior to the grating because the contact area of the FRP grating cover is larger than that of the grating.

Application

★ Community walkway, garden fountain cover, stair tread, car wash grating cover

★ Factory: sewer cover, pool cover, operating platform, stair tread, floor walkway

★ Urban Greening: well cover, cable trench cover, trench cover, trench cover, sewer cover, pipe cover, tree tweezers, etc.

Production Process

Different from the molding and pultrusion process of the grid plate, the FRP grating cover belongs to the hand paste process. This hand paste process is used to make various kinds of fiberglass products, such as the common fiberglass fans, fiberglass sculptures, fiberglass garbage cans, fiberglass septic tanks and so on. There are usually two ways to make the FRP grating cover. The first way is to make the cover on the surface when the grating is finished but not removed from the molding equipment. Another method is to put the removed grating on the other operating platform and make the cover. Both have advantages and disadvantages.

Reviews

There are no reviews yet.