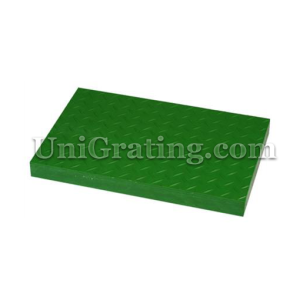

GRP molded floor grating provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Mach’ offers ECR glass fibers and four kinds of resin for choice

| Orthophthalic (Ortho) | Ortho resin is resistant to atmospheric corrosion. |

| Isophthalic (ISO) | ISO resin is suitable for a corrosive and chemical environment and is highly fire-resistant with controlled spreading of smoke. |

| Vinylester (VE) | VE is resistant to chemicals, such as acids, salts, and other corrosive substances. This type of resin is also highly fire-resistant. |

| Phenolic | Phenolic resin is resistant to chemicals and is extremely fire- resistant and gives off very little smoke. |

◆ Thickness/Height of grp floor grating

13mm, 15mm, 20mm, 25mm, 30mm, 38mm, 40mm, 50mm, 60mm,70mm

◆ Mesh Size of grating

standard mesh size 38x38mm, 40x40mm, 50x50mm, 25x100mm etc.

mini mesh size 20×20/40x40mm,19×19/38x38mm

micro mesh size 13×13/40x40mm

◆ Panel size of grating

1220x3660mm, 1000x3000mm,1007x4007mm etc.

please download our catalog for more details or feel free to contact us for suggestions.

◆ Surface of grating

Concave Surface, Smooth Surface, Gritted Surface, Top Solid Cover

The Advantages Of GRP Floor Grating

Comparing with other floor materials,GRP floor grating provides a series of benefits, unmatched impact resistance, while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install. GRP floor grating is made of continuous fiberglass fully soaked in unsaturated polyester resin giving a uniform structure and perfect bi-directional mechanical properties.

◆ GRP floor grating Features:

◆ Corrosion and chemical resistant

◆ High strength-to-weight ratio

◆ Fire retardant

◆ Ergonomic

◆ Slip-resistant

◆ Anti-aging

◆ Easy maintenance

|  |  |

Application Of GRP Floor Grating

GRP floor grating is acid-base corrosion resistant, insulating and easy to install, so can be applied in various place, sometimes grp floor grating can be applied as a system gratings, handrails and connection fittings. They are used in power plants, chemical plants, water treatment and oil platforms and other corrosion environment.

Application Case

What kind of FRP grating should be selected in chemical plant workshop?

The grating is mainly used for workshop ditches, walkways and operation platforms.

Several factors should be considered, such as corrosion resistance, flame retardant, strength and so on.

1. Chemical plant workshop has many ditches, mostly corrosive liquids. Traditionally, stainless steel, cast iron or cement cover are mostly used. These materials are not acid-alkali resistant and have poor corrosion resistance.

We know that the greatest point of FRP grating is acid and alkali resistance, corrosion resistance, high strength, conducive to the ground dirty water into the ditch, but also conducive to anytime and anywhere to investigate the situation in the ditch.

FRP grating with excellent Ortho, ISO, Vinyl resin will have excellent corrosion resistance performance.

2. Secondly, the glass grating is much lighter than the traditional material and easy to handle.

FRP grating distribute load components evenly, which is helpful for long-term operation and can extend the service life of grating very well.

3. Thirdly, we all know that fireworks are strictly prohibited in chemical plants. The FRP gratings of our company have passed the SGS ASTME-84 flame retardant test.

They have better flame retardant and fire retardant functions and are more secure to use.

Reviews

There are no reviews yet.