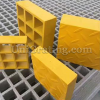

Product Introduction

Fiberglass trench drain grates are ideal alternative to drain cover because of its longer life and ability to withstand heavy loads. Nowadays, drain cover is generally made of FRP material, because this material has the advantage that other materials can’t match. When the FRP material is not popular, the drain cover is generally made of concrete, steel fiber reinforced concrete, cast iron, ductile iron, PVC, etc., but these materials have the disadvantages of low bearing efficiency and deterioration of corrosion performance.

Compared with the wood: the fiberglass trench drain grates are stronger than the wood, and the fiberglass trench drain grates does not need to be like a wooden cover. The board is prone to decay and requires frequent color maintenance. Compared with plastics: it is not inflammable except for the quality of the plastic grille. The fire performance is much higher than that of the plastic cover. Everyone knows that plastic burning is not difficult. Fight and break down substances that are harmful to the human body.

Fiberglass trench drain grates generally use a 38*38*38mm FRP grating. If the bearing is heavy, you can choose a 50*50*50mm or 38*38*65mm FRP grating.

Benefits

Corrosion Resistance: One of the main advantages of fiberglass trench drain grates is the non-corrosive nature of the material. It helps eliminate the need for additional lining materials and surface protection coatings.

Light Weight: Compared to traditional drain covers, fiberglass trench drain grates is an effective alternative to the high strength-to-weight ratio.

Anti-theft: The zero scrap value of Fiberglass trench drain grates prevents the cover from being stolen and prolongs its service life.

Resilient: It can be exposed to the weather or the sun without any impact on safety or aesthetics.

High Strength: It uses fiber reinforced plastic 40% lighter than conventional precast concrete and cast iron hoods, and has a compressive strength 5 times higher, able to withstand heavy-duty vehicle traffic moving over it.

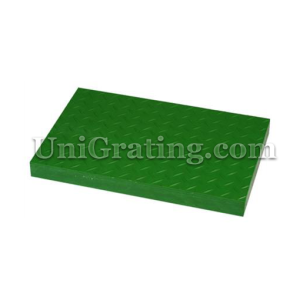

Beautiful Appearance: A variety of decorative surface design options, color variations and logo embossing options for high-end applications.

Maintenance Method

1. No other maintenance methods are needed during the use, just use the washing liquid to clean the surface dust and dirt.

2. In the course of use, direct contact between various open flames and high temperatures such as electric welding and oxy-acetylene flames during steel structure and equipment maintenance should be avoided.

3. In the process of use, the dragging, impact damage and paint pollution of various steel products, steel sharp tools and tools should be avoided during the maintenance of steel structure and blending equipment.

4. In the process of use, pay attention to the following do not have hard debris and other objects, so as not to affect the service life.

Reviews

There are no reviews yet.