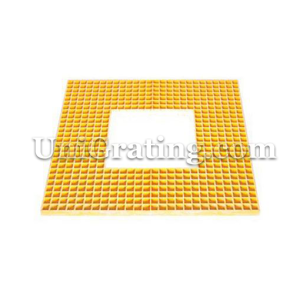

38mm(1.5”) thickness GRP grating is the most widely used. It is usually used in car washes, sewage treatment plants, chemical plants and other places where there are cars going around, which can carry about 3.5 tons of cars. If greater load capacity requirements are required, it can be achieved by increasing the thickness of the grating.

Size Chart-38mm Thickness GRP Grating

Commonly used specifications for 38mm(1.5”) grp gratings are 38×38×38, 19×19/38×38 micro-hole gratings and 38×25×50 heavy-duty grating. Mach’s also offers you customized service.

| Diagram/Example | Mesh Size (mm) | Load bar thickness (mm) | Panel sizes available(mm) | Open area | Weight (kg/m2) |

| 38×38 | 7.0/5.0 | 1524×4000, 1220×4000,1220×3660,1220×2440,915×3050 | 68% | 19.5 |

| 19×19/38×38 (double layer mini mesh) | 7.0/5.0 | 1524×4000,1220×3660,1220×2440,915×3050 | 40% | 25.3 | |

| 26×26/52×52 (double layer mini mesh) | 6.0/5.0 | 1150×4011 | 60% | 19.5 | |

| 25×50 (heavy duty) | 11.0/9.0 | 1220×3660 | 48% | 30.30 | |

| 25×100 | 8.0/6.0 | 1220×3660 | 52% | 22.50 | |

| 38×100 | 8.0/6.0 | 1220×3660,1220×2440,915×3050 | 65% | 16.40 | |

| 25×152 | 9.0/6.5 | 1220×3660,1220×2440,915×3050 | 63% | 22.50 | |

| 38×152 | 8.0/6.0 | 1220×3660,1220×2440,915×3050 | 67% | 15.92 | |

| 25×100 (imitation pultruded) | 15.0/5.0 | 1220×3660 | 62% | 21.00 | |

| 38×152 (T type) | 15.0/8.0 | 1220×3660 | 62% | 18.60 | |

| 25×152 (stair tread) | 7.0/5.0 | 565×3050 | 62% | 23.10 | |

| 38×152 (stair tread) | 7.0/5.0 | 580×3660,610×3660 | 65% | 17.00 |

Application-38mm Thickness GRP Grating

◆ Car Wash Shop: 38mm GRP grating can carry about 3.5 tons of cars, and and it is better that the support distance (horizontal and vertical) below does not exceed 50cm during installation.

◆ Walkways: Generally 38mm GRP grating is used in factories for workers to walk, requiring less bearing capacity.

◆ Operating Platform: The working platform of workers in the factory has certain flexibility and improves work comfort.

◆ Stair Treads: 38mm thickness GRP stair treads bear the weight of the person and has lower requirements on the bearing capacity.

Packaging Details

1. We place FRP grating products on iron plates protected with anti-oxidation paint. The package size depends on the actual factory dimensions of the product.

2. We put foam paper between the grating products and the floor and fix it with tape. Finally, we seal with plastic film, so that the product can be effectively protected.

Reviews

There are no reviews yet.