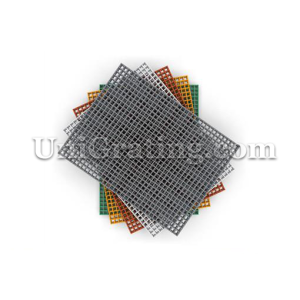

GRP grid flooring produced by Mach’s is made from pre-buried grit finish, which means that the non-slip grit is pre-buried on the surface of the grille during the manufacturing process, creating an integral bond between the grit and the grille surface. This ensures that the non-slip sand does not peel off the grille, and does not damage the slip resistance or resilience of the grille.We have multiple sizes for applications ranging from industrial water treatment plants to pedestrian areas requiring public access.

The square mesh structure of GRP grid flooring has bidirectional strength that goes beyond the unidirectional nature of steel metal grids. Due to the bi-directional strength of the grating, the end lashing and additional support around the pipe bracket can be eliminated, and the GRP grille floor can be easily installed.In addition, there is a range of surface treatments, including meniscus, grit and smoothness to meet the most stringent anti-slip and easy-to-clean requirements.

The Benefits Of GRP Grid Flooring On Tradinitonal Materials

1. Strong Skid Resistance

The surface of our product has a groove anti-slip design, which greatly increases the friction coefficient and has reliable safety.

2. Light Weight, High Strength, Easy To Cut And Install

GRP grid flooring is 1/3rd the weight of equivalent steel grating.Mach’s GRP products have an excellent strength to weight ratio. Our superior lightweight products have similar weight strength properties as steel.

3. Corrosion Resistant, Never Rust, Maintenance Free

For the acid, base, salts, organic solvents and other kinds of corrosive environments, GRP grid flooring has an excellent corrosion resistance.

4. Flame Retardant

The flame retardant rate of ordinary flame retardant grids does not exceed 25; the flame propagation rate of flame retardant vinyl grids does not exceed 10. The oxygen index is not less than 28.

5. Long Service Life

GRP grid flooring has a service life of more than 50 years, 5 years of metal, 3 years of wood, and 10-15 years of wood-plastic composite.

6. Impact Resistance

A severe impact can cause permanent damage to the metal grating. The inherent flexibility of our GRP products means that they are not damaged by major shocks.

7. It Is Highly Configurable, Flexible In Size And Dimensionally Stable.

8. Low Cost And Good Economic Benefits.

Quality Identification

A. Selection of raw materials

The raw materials used for the GRP grid flooring are resin, fiberglass fiber, and filler calcium powder are arranged in a ratio of 1:1:1. The high quality frp grating is made of high quality resin: unsaturated ortho-phenyl resin 196, colorless and transparen. Low viscosity, low heat release, low shrinkage, high speed curing, high speed compatibility, bright gloss. The grating produced is flat and smooth, with good gloss, great strength and certain toughness. If the use of poor quality resin will be completely the opposite of poor quality resin turbidity, high viscosity, high heat release, high shrinkage, curing relatively slow, poor compatibility, the production of fiberglass grates porous, easy to fracture, poor strength and toughness.

The filling of the FRP grating is calcium powder or aluminum powder. The high-quality filling powder is fine and white, has flame retardancy, and is completely fused with the resin. The produced board has beautiful color and good transparency and toughness. On the contrary, the inferior filler powder is rough and dull, not flame retardant, and the produced board has no glossiness and is relatively brittle and has no toughness.

Good Material

Vs

Bad Material

B. Comparison of finished products

The high-quality FRP grating products have no obvious cracks, fewer pores, bright and pure color, good transparency, certain toughness, good surface finish and long service life. The inferior FRP grating products have cracks. There are many stomata and the color is not pure and the gloss is not enough. Its service life is also short.

Although the FRP grating can not completely replace the steel grating, it completely compensates for the conditions or fields that the steel grating cannot meet. It fully reduces the non-capacity burden of the steel grating, and also provides people with another solution to solve the problem. Its emergence has become a powerful complement to steel gratings.

Reviews

There are no reviews yet.