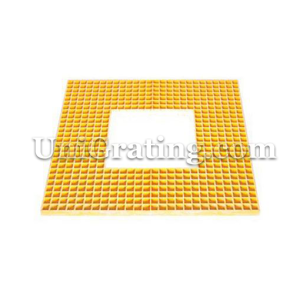

GRP floor grating is a type of polyester plate prepared by molding process with many rectangular and square spaces in regular distribution, which has bi-directional mechanical characteristics. It can be widely used in petroleum, chemical electronics, electric power, paper industry, printing and dyeing, electroplating, Marine exploration, sewage treatment and other industries of work platform, equipment platform, drilling platform, walkway, etc.

Types Of Grp Floor Grating

1.According to the resin type of the grating

There are three common resin types: o-benzene, meta-benzene, and vinyl. The price is proportional to the corrosion resistance:

(1) O-benzene type: common corrosion resistance, can resist atmospheric aging, seawater corrosion, long-term use temperature -50~60℃.

(2) Benzene (municipal): excellent corrosion resistance, can withstand medium concentration of inorganic acid, salt and other environment, long-term use temperature -50~90℃.

(3) Vinyl (chemistry): good corrosion resistance, can withstand acid, barium, salt, solvent, acid, acid and other harsh corrosion environment. The long-term service temperature is -50~110℃.

2. Depending on the application to select the type of fiberglass grating surface: Normal type grating and Cover type grating

Normal type:

(1) Concave (naturally formed): the concave grating is basically anti-skid.

(2) Surface sanding: sanding grating is especially anti-skid.

(3) Smooth surface: smooth grating is non-skid, generally used for decoration and other occasions where require smooth surface.

Cover type grating (It is suitable for occasions with no holes, no leakage, no gas volatilization or special requirements for holes).

(1) Smooth cover type: non-slip surface, easy to dust.

(2) Quartz sand cover type: sand cover grid with the best skid resistance.

(3) Patterned cover type: it is a little slippery, but even more beautiful.

3. According to the colors to choose

Mach’s standard colors are green, yellow, and gray. It is recommended that you choose different color grids according to different environments and occasions to make the work more user-friendly.

Green fiberglass grating: green, long-term work will not cause visual fatigue.

Yellow fiberglass grating: safety, warning color, mainly used in more dangerous situations, such as: power distribution room, high-altitude walkway, etc.

Reviews

There are no reviews yet.