FRP molded heavy loading gratings can hold a heavy load than normal fiberglass gratings do. Due to its thick wall of the lattice, they have a high load capacity. GRP molded gratings are usually used in places where require a large load.

Fiberglass molded gratings for heavy load are made of resin and fiberglass. The density of the fiberglass grating is no more than 2 kg per cubic decimeter, only 1/4 of steel and 2/3 of aluminum. The strength of the fiberglass grating is 10 times higher than that of rigid PVC, and the strength exceeds that of aluminum and ordinary steel. Since the fiberglass grating has a light weight, it can significantly reduce the basic support, thereby reducing the material costs of the project. Cutting and installing fiberglass grating is very simple, there is no need for hot fire and large lifting equipment, only a small amount of hand and power tools, so the installation cost is significantly reduced.

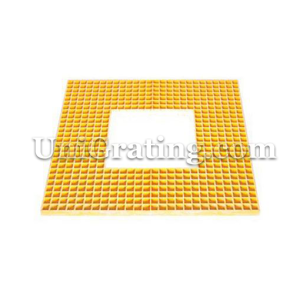

The size of the fiberglass molded grating heavy loading:

1. 25mm Height Mesh 25 * 100 Panel Size 1220 * 3660

Wall thickness: top part 9.5mm, low part 8mm, Weight 19.5kg / m2

2. 50mm Height Mesh 25 * 50 Panel Size 1220 * 3660

Wall thickness: top part 12mm, low part 9mm, Weight 41kg / m2

3. 38mm Height Mesh 25 * 50 Panel Size 1220 * 3660

Wall thickness: top part 11mm, low part 9mm, Weight 30.3kg / m2

4. 60mm Height Mesh 38 * 38 Size of the panel 1220 * 3660

Wall thickness: top part 11.5mm, low part 9mm, Weight 50.4kg / m2

5. 50mm Height Mesh 38 * 38 Size of the panel 1220 * 3660

Wall thickness: top part 11mm, low part 9mm, Weight 42kg / m2

6. 30mm Height Mesh 38 * 38 Size of the panel 1220 * 3660

Wall thickness: top part 10.5mm, low part 9mm, Weight 25kg / m2

Features of fiberglass grating for heavy loading:

1. Fiberglass grating is made by interlacing fiberglass and is cast from resin.

2. The glass fiber is intertwined, and the resin is completely saturated, so the grille has a good resistance to corrosion.

3. The overall lattice design evenly distributes the load, which contributes to the uniform installation effort of the lattice and its supporting structure.

3. The glossy surface of the lattice and the italic surface of the lattice make the lattice self-cleaning.

4. The concave surface makes the grid anti-slip, and the anti-slip effect of the gritted surface is better.

Reviews

There are no reviews yet.