Whether in slippery environments such as mud, snow, ice, and sand, or in corrosive environments such as chemical plants and wastewater treatment plants, traditional materials like steel or aluminum will fail when used for walkways, causing many safety issues. Fiberglass grating is the ideal material for the walkway.

If you need a more cost-effective fibreglass walkway grating for corrosive environments, but surface area or strength requirements are not too high, molded fibreglass walkway gratings are recommended. When your project requires a larger surface area and a higher strength walkway grating, the pultruded fibreglass walkway grating is a better choice. It is worth noting that when choosing a pultruded fibreglass walkway grating, the load-bearing capacity of the material must be evaluated. Unlike molded gratings, fiberglass pultruded gratings have strong strength only in the direction of the bearing bars.

Detailed Dimension

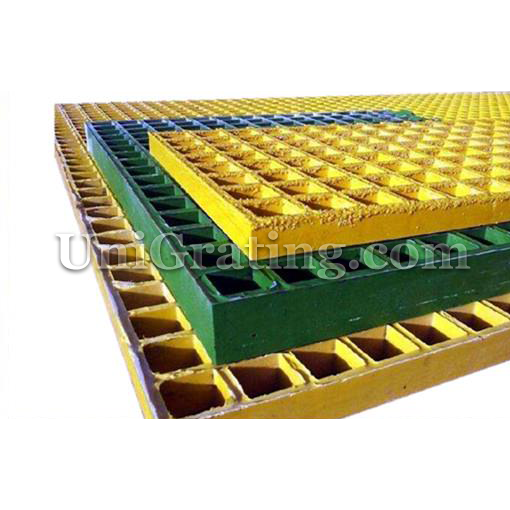

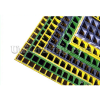

Most of our fibreglass walkway gratings are dark gray and yellow. For custom requirements, we also have light gray, green and red.

■ Molded Fibreglass Walkway Grating

The most common molded grating panel sizes are 915×3050, 1220×2440, 1220×3660mm.

| Example | Thickness (Mm) | Mesh Size (Mm) | Load Bar Thickness (Mm) | Open Area | Weight (Kg/M2) |

| 25 | 38×38 40×40 50×50 83×83 19/19×38×38 25×100 | 6.4/5.0 7.0/5.0 7.5/6.0 7.5/5.0 6.5/5.0 6.5/5.0 | 68% 67% 78% 84% 40% 67% | 12.30 12.30 11.50 5.80 16.80 13.83 |

| 30 | 38×38 38×38(High Load) 40×40 12.7×12.7/38×38 20×20/40×40 | 6.5/5.0 10.5/9.0 7.0/5.0 7.5&4.5/38×38 7.0/5.0 | 68% 58% 67% 30% 42% | 14.60 25.00 14.60 22.00 18.00 |

| 35 | 38×38(High Load) | 10.5/9.0 | 56% | 29.40 |

| 38 | 38×38 19×19/38×38 26×26/52×52 | 7.0/5.0 7.0/5.0 6.0/5.0 | 68% 40% 60% | 19.50 23.50 19.50 |

| 40 | 40×40 83×83 20×20/40×40 | 7.0/5.0 7.0/5.0 7.0/5.0 | 67% 84% 42% | 19.20 9.50 23.70 |

| 50 | 38×38(High Load) 50×50 50×50 25×25/50×50 | 11.0/9.0 7.0/5.0 8.0/6.0 8.0/6.0 | 56% 78% 78% 55% | 42.00 20.80 23.70 28.50 |

| 60 | 38×38(High Load) | 11.5/9.0 | 54% | 50.40 |

| 63 | 50×50 | 8.3/6.0 | 78% | 28.80 |

Note: The orange models are marked in the table, in addition to the conventional Orthophthali, Isophthalic, and Vinyl ester resin gratings, they can also be produced into phenolic gratings.

■ Pultruded Fibreglass Walkway Grating

| Diagram/Example | Model | Thickness (Mm) | Load Bar Width(Top/Bottom) (Mm) | Open Area |

| I-4100 | 25 | 15/15 | 40% |

| I-5010 | 25 | 15/15 | 50% | |

| I-6010 | 25 | 15/15 | 60% | |

| I-40125 | 32 | 15/15 | 40% | |

| I-50125 | 32 | 15/15 | 50% | |

| I-60125 | 32 | 15/15 | 60% | |

| I-4015 | 38 | 15/15 | 40% | |

| I-5015 | 38 | 15/15 | 50% | |

| I-6015 | 38 | 15/15 | 60% | |

| T-1210 | 25 | 38/15 | 12% | |

| T-1810 | 25 | 41.3/15 | 18% | |

| T-2510 | 25 | 38/15 | 25% | |

| T-3310 | 25 | 41.3/15 | 33% | |

| T-3810 | 25 | 38/15 | 38% | |

| T-1215 | 38 | 38/15 | 12% | |

| T-2515 | 38 | 38/15 | 25% | |

| T-3815 | 38 | 38/15 | 38% | |

| T-5015 | 38 | 25/15 | 50% | |

| T-3320 | 50 | 25/15 | 33% | |

| T-5020 | 50 | 25/15 | 50% | |

| HL-4020 | 50 | 15 | 40% | |

| HL-5020 | 50 | 15 | 50% | |

| HL-6020 | 50 | 15 | 60% |

Reviews

There are no reviews yet.