Introduction

Fiberglass dock grating solves the corrosion of the port caused by Marine harsh weather in a good way with a special processing technology.Traditionally, steel grilles are often used as paving materials for wharves. The harsh climate of the ocean and the erosion of seawater cause serious corrosion of these materials, increasing the unsafe factors.Gradually, due to these chronic corrosion conditions, the use of traditional metal grille is not good enough to meet the needs of users.Long-term use of metal grille is prone to rust, damage, etc., and there are certain safety hazards.

Many countries have successfully used fiberglass dock grating in such a harsh environment. Due to three quarters of weight reduction, components such as basic support can be more easily processed and can reduce the total cost of the platform after proper design.

The Benefits Of Using A FRP Grating As A Dock Deck

- Unlike the steel gratings, Mach’s sidewalk panels were made of lightweight fiberglass, eliminating the time-consuming and laborious use of heavy equipment to install heavy dock materials one after one. Our fiberglass dock grating can be quickly installed, because each can cover up to 80 square feet of surface area.

- Easy to cut, they can be fixed to existing support structures with specially designed clips. Fiberglass terrace potential is better than wood, in which wood can degrade rapidly in wet environment, crack and crack can occur in freeze-thaw cycle, and is affected by detergent and de-icing chemicals. Fiberglass dock grating, on the other hand, can satisfy all requirements in passenger traffic, rolling vehicles and busy port environments.

- With a resin content of 60-65%, the glass fiber is protected from corrosive materials. Resin systems protected from a variety of acids, caustic and salt corrosion can also be customized. Mach’s can make a variety of FRP gratings according to your needs!

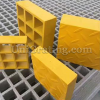

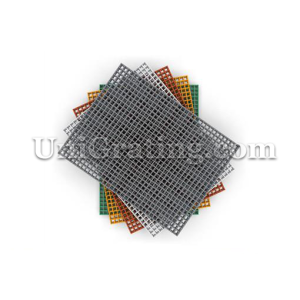

- There are also a variety of colors and depths to choose from, which means we have ready-made solutions no matter how much load capacity and span strength you need.

Types Of Fiberglass Dock Grating

Mini Mesh Grating

Mini mesh fiberglass dock grating is complliant mesh size.This small mesh also prevents small tools and other objects from falling through the grating, protecting personnel or equipment below.Micro mesh gratings can be made with or without a non-slip coating in a mesh structure, available in light grey and dark grey.

Rectangular Mesh Grating

Rectangular Mesh fiberglass dock grating is both versatile and flexible in industrial applications. When selecting grating, be certain to review the “Resin and Color Selection Guide” for your application. It is available in 1-inch, 1.5-inch and 2-inch square grids, with open areas ranging from 68% to 78%.

Super Span Grating

Mach’s SuperSpan molded fiberglass grating is designed specifically to provide a solution to expand the range of application of molded grating into applications where larger spans are required or desired.It is also named High Load Capacity (HLC). It provides a non-slip surface coating with an open area of 38% and 55%.

Our Advantages

1. We are the manufacturer , and we are equipped with all the related equipment for production. 15 years’ experience in production, management and professional sales team.

2. Our raw material is the glass fiber of JUSHI GROUP Co., LTD. We use the products of China Aluminum Co., Ltd. as the filler. Our raw materials must be strictly tested before they can be put into production.

3. We have production process inspection and pre- delivery inspection to ensure product quality.

4. The new employees have to practice with experienced workers before they go on duty. For some high demand products, we will give the staff professional training to ensure that the products meet the high requirements of the customers.

5. All products meet both European and American quality standards, all products are Approved by ISO, ABS, SGS, ASTM E84.

Reviews

There are no reviews yet.